Summary

See how we helped HMY Yudigar, a global shopfitting partner who is committed to a sustainable and circular economy, to improve the packaging for one of its retail technology products. Moving from a multi-material pack using unsustainable materials, to a mono-material paper-based solution proved to be a game changer. The clever design from Smurfit Kappa allowed HMY Yudigar to not only achieve their sustainability objectives but also simplified the packaging process resulting in a reduction in raw material costs combined with labour savings due to reduced assembly times.

The Challenge

HMY Yudigar, a global shopfitting partner, was looking for an urgent solution to improve the packaging for one of its retail technology products. The wheeled electronic cabinet weighed 55kg and only four of the cabinets could be shipped on a standard Euro pallet, double stacked.

The previous packaging solution used five different materials to pack the product:

- Foam: Used as edge protectors

- EPS: Used to cushion the product in transit

- Wood: Used to lift the product to allow space between the wheels and the pallet base.

- Stretch film: Used to secure the wood around the wheeled base

- Cardboard: Used as the outer packaging to protect the product in transit

This multi-material solution caused HMY Yudigar a multitude of issues:

- Slow assembly time

- Complex packaging inventory

- High material costs

- Not all materials were sustainable

The Approach

Aware this was an urgent project, our design team went to work straight away using their knowledge and expertise to solve the issues. They knew immediately this needed to be a mono-material solution using only sustainable paper-based packaging.

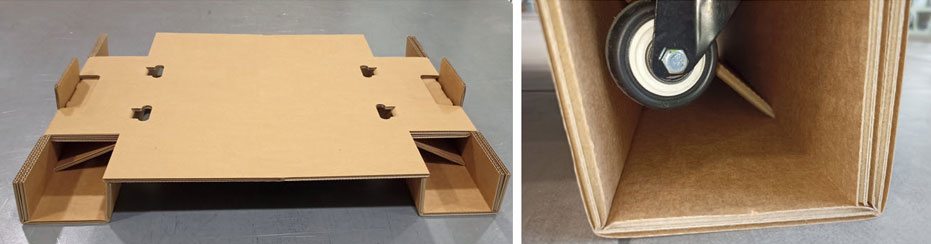

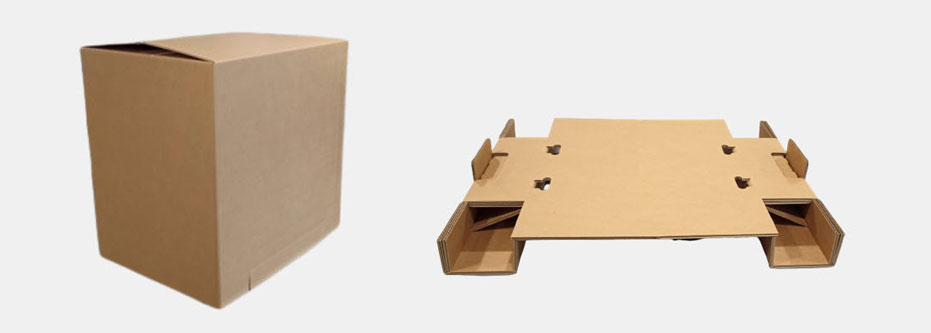

The first part of the solution was to develop a corrugated cardboard pallet base on which the cabinet would sit on. The cleverly designed pallet base ensured the wheels were lifted from the pallet so they could not be damaged in transit. The second part of the solution was a double-walled outer box that fitted over the top of the cabinet to meet with the corrugated pallet base.

To ensure the cabinet would be protected across the supply chain, our designers used our unique Paper to Box™ software which selects and creates the most suitable composition of papers to meet the required packaging performance.

In our in-house laboratory we also performed a Box Compression Test (BCT) to test the compressive strength of the box, according to international standards. Using these scientific insights we were able to evaluate the proposal to guarantee a risk-free solution, even when the cabinets were stacked in transit.

The Result

Within a matter of hours, Smurfit Kappa was able to develop an innovative mono-material solution for Yudigar consisting of just two items, a pallet base and an outer box. This innovative pack resulted in the following:

Reduction in material cost

As corrugated board is a strong yet cost effective material, they were able to eliminate the foam, eps, wood and stretch film from the packaging solution. This resulted in a 22% saving in raw material costs in comparison to the previous packaging.

Reduced Assembly Times

The new two-piece design was much quicker for the HMY Yudigar team to assemble and pack. This resulted in 46% reduction in packaging assembly times.

Simplified Packaging Inventory

Instead of ordering, managing, and storing five different packaging materials from a number of different suppliers, HMY Yudigar now has one supplier, supplying one material to meet the needs of this project.

More environmentally friendly solution

Paper-based packaging is one of the most sustainable materials available: it’s recyclable, renewable and biodegradable. The new design allowed HMY Yudigar to remove 10.4 tonnes of plastic from the project and achieve 9,790 kg of CO2 savings.

Supports the HMY Yudigar Smart Eco commitment

Smart Eco is HMY Yudigar’s commitment that seeks efficiency in the supply chain of the products they develop for their customers. This evolves towards a sustainable production model based on the circular economy and conceptualized from eco-design.

Packaging is an easy first step to help customers achieve their sustainability targets and that’s the role of Better Planet Packaging – to make a positive impact on billions of supply chains and consumers by reducing the environmental impact of packaging and its impact on the planet.