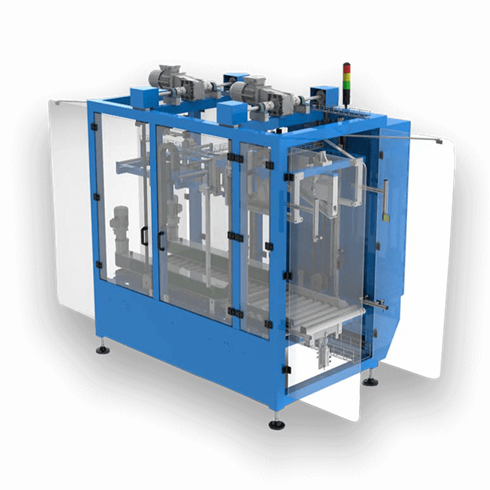

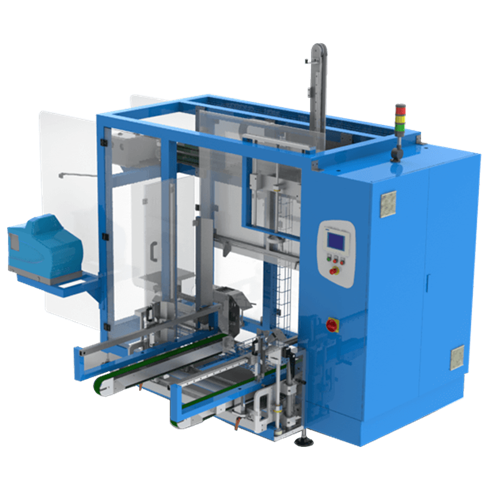

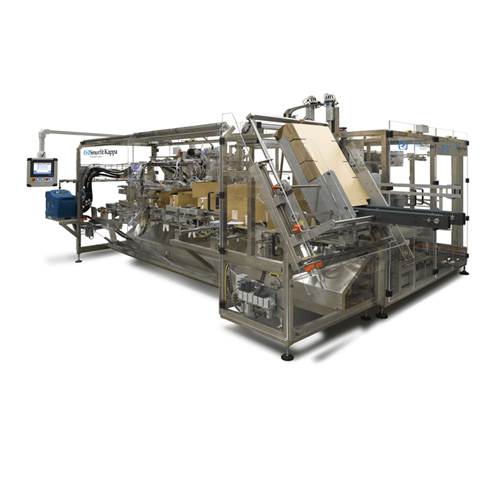

Robotics offer maximum flexibility in product handling allowing for products to be collated, packed and palletised in various orientations and patterns, all on the same machine.

We offer a range of intelligent robotic solutions to maximise productivity and minimise costs including:

-

Two axis robots for simple case loading

-

Four axis robots for more complex case loading and palletising applications

-

High-speed automated pick and place robotics

Our robotic solutions can be fitted with integrated vision systems for product detection, orientation and quality control. Their multi-tasking capability eliminates duplication and repetitive tasks such as product turning and specialised product coding

Robotics are adaptable to your packing needs both now and in the future and can simply be reprogrammed to accommodate new products, sizes, collations and pallet patterns when needed.

Robotics also allow for systems equipment to occupy a smaller footprint, ideal for integrating into the production and palletising area.

New products, sizes, collations and pallet patterns can easily be accommodated should business requirements in the future dictate.